Gummy Machine

Produce a variety of gummies with precision - all in one machine.

เจลาติน

เจลาตินจากปลา

เจลาติน เกรดพิเศษ

เจลาตินจากพืช

แคปซูลจากพืช

เครื่องผลิตซอฟท์เจล

เจลาตินแผ่น

เจลาติน

เจลาตินจากปลา

เจลาติน เกรดพิเศษ

เจลาตินจากพืช

แคปซูลจากพืช

เครื่องผลิตซอฟท์เจล

เจลาตินแผ่น

เครื่องผลิตกัมมี่

| Machine Model | SGDQ80 | SGDQ150 | SGDQ300 | SGDQ450 | SGDQ600 |

|---|---|---|---|---|---|

| Capacity | 80 kg/hr | 150 kg/hr | 300 kg/hr | 450 kg/hr | 600 kg/hr |

| Candy Weight | Depends on gummy size | ||||

| Depositing Speed | 45 ~ 55 pcs/min | ||||

| Working Condition | Temperature: 20~25°C; Humidity: 55% | ||||

| Total Power | 30Kw/380V | 35Kw/380V | 40Kw/380V | 45Kw/380V | 50Kw/380V |

| Total Length | 14 m | 18 m | 18 m | 18 m | 18 m |

| Gross Weight | 2500 kg | 3000 kg | 4500 kg | 4500 kg | 4500 kg |

The gummy products produced from this production line.

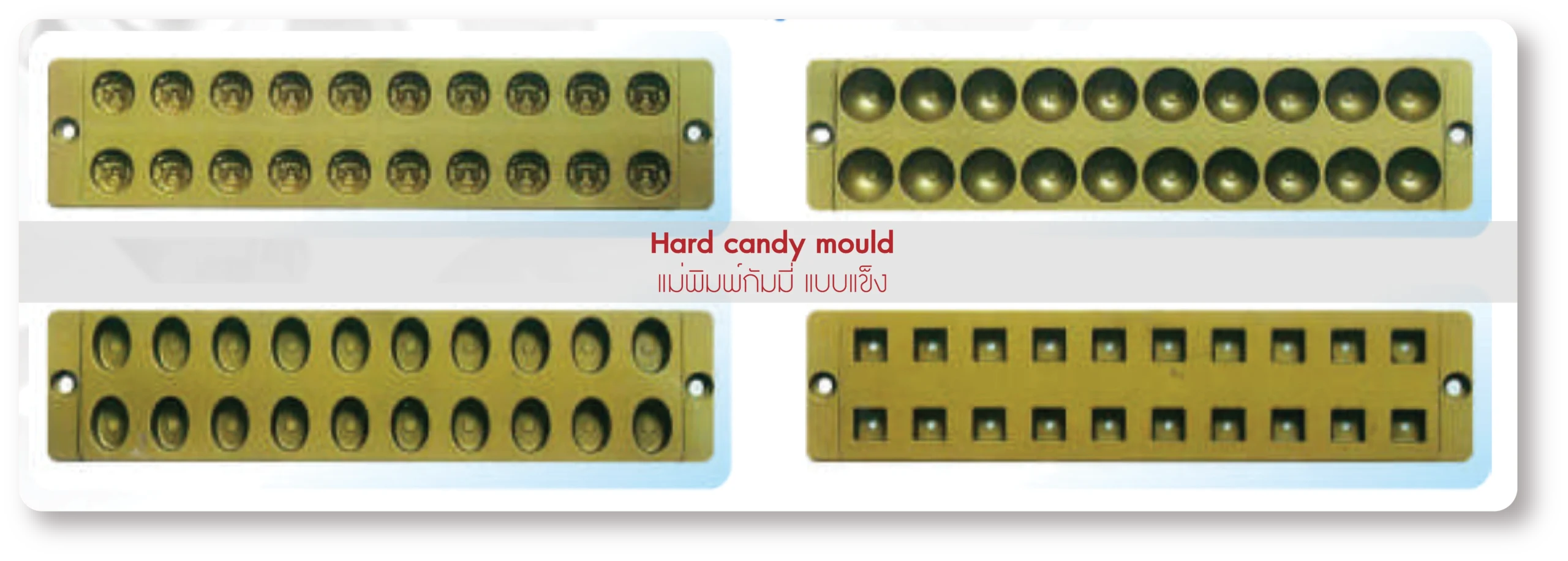

The jelly gummy candy depositing line is a modern continuous production system that our company has continuously researched and developed for producing high-quality gummy products. It can create gummies that are chewy, bouncy, and enjoyable to eat—without being too hard or too sticky. The molds or depositing nozzles can be changed as needed.

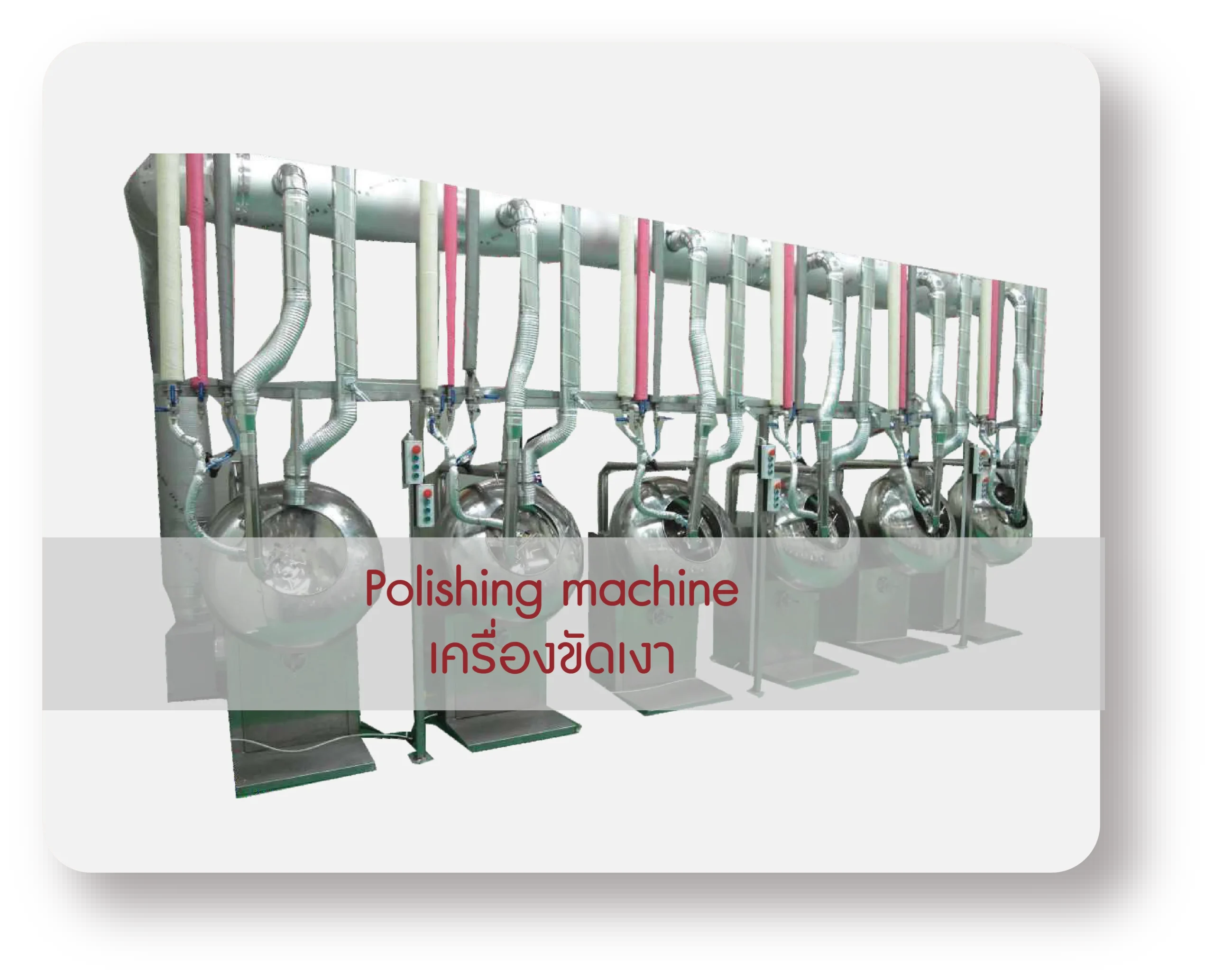

The entire system includes a jacketed melting tank, a jelly cooker, a holding tank, a depositor, a conveyor belt, a cooling tunnel, a sugar-coating machine (optional), and a gummy polishing machine (optional). It supports various gummy ingredients such as gelatin, pectin, carrageenan, and gum arabic.

This automated production process helps save time, labor, and space, and effectively reduces production costs. Additionally, an electric heating system is available as an optional feature, depending on user requirements.

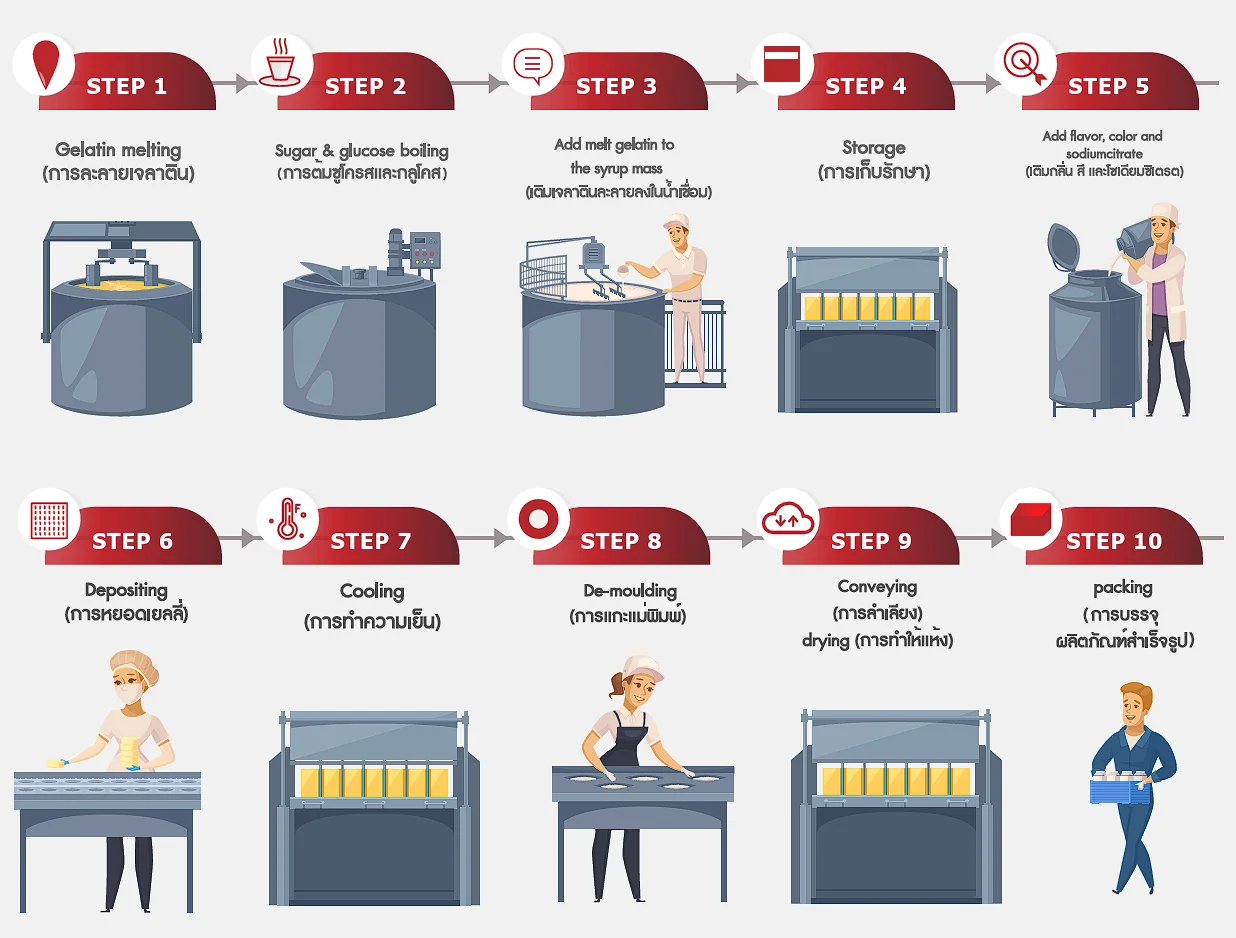

Diagram of the jelly gummy candy depositing production process.

FMQ1000 / FMPQ620 / FMPQ820 – Starch Mogul Line Production System.

| Model | FMQ1000 |

|---|---|

| Capacity | 600~1200 kg/hr |

| Candy Weight | Depends on gummy size |

| Depositing Speed | 25~35 pcs/min |

| Steam Requirement | 250 kg/hr at 0.5~0.8 MPa |

| Compressed Air Requirement | 0.2 m³/min at 0.4~0.6 MPa |

| Working Condition | Temperature: 20~25°C; Humidity: 55% |

| Total Power | 30 kW / 380 V |

| Total Length | 40 m |

The gummy candies produced by this production line.

| Model | FMPQ620 | FMPQ820 |

|---|---|---|

| Capacity | Depends on gummy size | |

| Gummy Weight | 10~30 pcs/min | 10~30 pcs/min |

| Depositing Speed | 250 kg/hr (0.5~0.8 MPa) | 300 kg/hr (0.5~0.8 MPa) |

| Compressed Air Requirement | 0.2 m³/min (0.4~0.6 MPa) | 0.2 m³/min (0.4~0.6 MPa) |

| Working Condition | Temperature: 20~25°C | Humidity: 55% |

| Total Power | 18 kW / 380 V | 27 kW / 380 V |

| Total Length | 15 m | 18 m |

Laboratory Equipment (Lab Equipment)

The advantages of using this model are its small size, lightweight, attractive appearance, and ease of use. It is suitable for gummy manufacturers or ingredient producers who want to professionally develop new formulas or products.